In the quest for enhanced efficiency and precise measurements in fluid management, low flow sensors have emerged as indispensable tools across various industries. These innovative devices are designed to measure the flow rate of liquids and gases with remarkable accuracy, addressing the growing demand for effective monitoring solutions. As businesses and organizations strive for operational excellence, understanding the capabilities and applications of low flow sensors becomes crucial for optimizing resource utilization and minimizing waste.

The significance of low flow sensors is particularly evident in sectors where fluid dynamics are critical, such as in water treatment, chemical processing, and HVAC systems. By providing real-time data, these sensors enable decision-makers to make informed choices, leading to improved process control and better energy management. Furthermore, the technological advancements in low flow sensing devices allow for increased reliability and longevity, making them a wise investment for companies looking to enhance their performance metrics.

In 2025, as we explore the top low flow sensors available in the market, this guide aims to provide comprehensive insights into their functionalities, benefits, and selection criteria. With this knowledge, professionals can better navigate the complexities of fluid measurement and ensure that their operations are both efficient and sustainable.

Low flow sensors play a crucial role in industries that require precise measurement of fluid flow, especially in applications where minimal flow detection is essential for operational efficiency and safety. These devices help ensure that systems operate within their optimal range, preventing issues such as overheating, waste, and system failures. According to the Flow Measurement and Control Market report by Research and Markets, the demand for low flow measurement devices is expected to grow significantly, driven by industries such as pharmaceuticals, chemical processing, and water management, which rely on accurate flow measurements to maintain quality and compliance standards.

Understanding the types of low flow sensors available and their specific applications can greatly enhance operational efficiency. For instance, vortex flow meters and thermal mass flow sensors are popular choices due to their accuracy and reliability in detecting low flow rates. By implementing these sensors, companies can minimize resource consumption and enhance productivity. A study by the International Society of Automation highlights that integrating advanced flow management systems can lead to a 20% reduction in operational costs, showcasing the economic benefits of adopting such technologies.

Tips: When selecting low flow sensors, consider factors such as the type of fluid, expected flow range, and environmental conditions. Regular maintenance and calibration of sensors can also significantly improve measurement accuracy and extend the lifespan of your equipment. Keeping up with the latest advancements in sensor technology can provide your operations with a competitive edge in efficiency and accuracy.

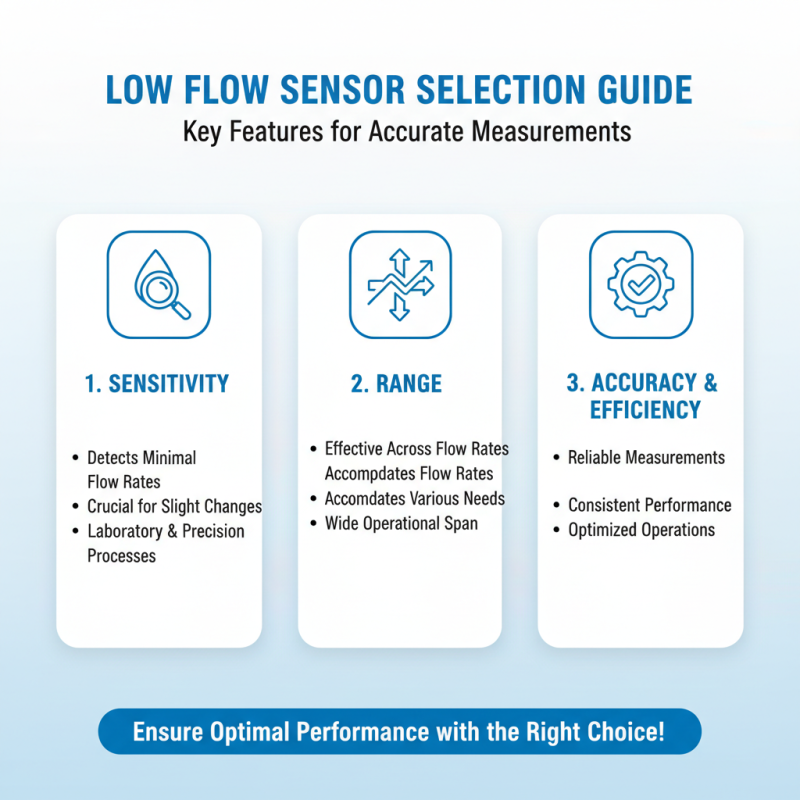

When selecting low flow sensors, several key features must be considered to ensure accurate measurements and operational efficiency. One of the primary aspects is the sensor's sensitivity, which determines its ability to detect minimal flow rates. High sensitivity is essential for applications where even the slightest changes in flow need to be monitored, such as in laboratory experiments or precision industrial processes. Additionally, the range of the sensor is crucial; it should be capable of functioning effectively across various flow rates to accommodate different operational needs.

Another important consideration is the sensor’s compatibility with the fluid being measured. Factors such as viscosity, temperature, and chemical composition can significantly impact sensor performance. Therefore, it is vital to choose a sensor that not only aligns with the specific fluid characteristics but also features appropriate materials for durability and longevity. Furthermore, the method of measurement—whether based on thermal, magnetic, or ultrasonic principles—should align with the application requirements to achieve optimal efficiency and reliability. Overall, understanding these fundamental features will aid in selecting the right low flow sensor for any given application.

Low flow sensors are essential tools that measure fluid flow rates in various applications, particularly where precise control and efficiency are critical. These sensors come in various types, including thermal, magnetic, and ultrasonic flow sensors, each offering unique advantages. Thermal flow sensors operate based on heat transfer principles, making them ideal for small flows of liquids and gases. Magnetic flow sensors utilize Faraday's law of electromagnetic induction, providing accurate measurements for conductive fluids. Ultrasonic flow sensors, on the other hand, use sound waves to determine flow rates, suitable for a wide range of applications including HVAC systems and water management.

When selecting a low flow sensor, it is crucial to consider the specific application requirements. For instance, thermal sensors are often more effective for small flow rates in clean fluids, while magnetic sensors can handle dirty fluids but require conductivity. Ultrasonic sensors can be advantageous where non-invasive measurement is preferred.

Tips: Always ensure that the selected sensor is compatible with the fluid type and conditions of your application. Regular calibration and maintenance can significantly enhance the accuracy and lifespan of your low flow sensors. Additionally, consider environmental factors, such as temperature and pressure variations, as they can impact sensor performance.

| Sensor Type | Measurement Range | Accuracy | Output Type | Applications |

|---|---|---|---|---|

| Coriolis Flow Sensor | 0.01 to 10 L/min | ±0.5% | 4-20 mA | Food and Beverage, Chemical |

| Turbine Flow Sensor | 0.05 to 200 L/min | ±1% | Pulse Output | Water, Oil |

| Ultrasonic Flow Sensor | 0.1 to 25 L/min | ±0.2% | Digital Output | HVAC, Water Management |

| Magnetic Flow Sensor | 0.01 to 15 L/min | ±0.5% | Analog Output | Chemical Processing, Water Treatment |

| Vortex Flow Sensor | 0.1 to 100 L/min | ±1% | Frequency Output | Hydraulic Systems, Gas Measurement |

When selecting the right low flow sensor for your applications, it’s crucial to consider various factors that can impact performance and efficiency. According to a report from the International Society of Automation (ISA), the accurate measurement of low flow rates becomes increasingly important in industries such as pharmaceuticals and water treatment, where precision is imperative. Choosing a sensor with the appropriate measurement range is vital; sensors that can handle flow rates from as low as 0.1 liters per minute up to 10 liters per minute are common, ensuring flexibility across different applications.

Another key consideration involves the technology behind the sensor. Options include thermal, electromagnetic, and ultrasonic sensors, each with specific advantages depending on the system requirements. For example, a study by the Flow Measurement and Instrumentation journal highlights that thermal flow sensors offer high accuracy even at low flow rates, making them suitable for applications where traditional methods fall short. Furthermore, understanding the fluid properties—like viscosity and temperature—is essential, as these can drastically affect measurement efficiency and sensor selection. By carefully evaluating these parameters, industries can optimize performance and reliability, moving toward more efficient operational processes.

Proper maintenance and calibration of low flow sensors are essential for ensuring their longevity and accuracy. Regular maintenance involves routine inspections to check for any signs of wear, debris accumulation, or component failure. Cleaning sensors with appropriate solvents or tools prevents buildup that could skew measurements, leading to inefficiencies or incorrect flow readings. It's also vital to regularly verify the sensor's alignment and condition, as a misaligned sensor can result in significant measurement errors.

Calibration is equally crucial for optimal performance. Depending on the application, low flow sensors should be calibrated at specific intervals to ensure accuracy. During calibration, the sensor should be exposed to known flow rates to assess and adjust its output as necessary. This process helps to identify any drift in measurements over time, allowing for timely corrections. Implementing a systematic calibration schedule not only enhances precision but also extends the sensor's operational life, ensuring reliable performance in various applications.

This chart illustrates the average flow measurements across different low flow sensor types in liters per minute (L/min). The data reflects typical performance metrics observed in laboratory settings, providing a visual comparison for efficiency.

As a specialist in environmental and flow sensor technology, ScioSense enables companies to use the planet’s resources more sustainably, helping to create a healthier future for all.