In the rapidly evolving landscape of industrial automation, the quest for precision has brought level sensors to the forefront of measurement technology. According to a 2022 report by MarketsandMarkets, the global level sensors market is expected to reach $5.2 billion by 2027, growing at a CAGR of 5.1% during the forecast period. This significant market growth underscores the increasing demand for accurate and reliable measurement solutions in diverse applications, ranging from water and wastewater management to chemical processing and food and beverage production.

Experts agree on the necessity of high-performance level sensors for optimizing industrial processes. Dr. Emily Roberts, a renowned expert in the field of automation technology, states, "Accurate measurement is crucial for operational efficiency; level sensors are instrumental in achieving that precision across various sectors." As industries prioritize efficiency and sustainability, the adoption of advanced level sensors is poised to revolutionize how companies manage their resources and operational workflows, ensuring that they remain competitive in a technology-driven marketplace.

The versatility and reliability of level sensors are essential as industries navigate the challenges of modern production demands. With innovations in sensor technology, including wireless capabilities and enhanced measurement accuracy, level sensors are not only meeting current requirements but also paving the way for future advancements in industrial measurement and control systems. As companies look to optimize their operations, the integration of sophisticated level sensors will undoubtedly play a pivotal role in shaping the future of industrial measurement practices.

Top Level Sensors play a critical role in industrial measurement technologies, facilitating precision and efficiency across various applications. These sensors are designed to monitor key parameters such as temperature, pressure, and fluid levels, ensuring that operations adhere to safety and performance standards. According to a report by MarketsandMarkets, the global market for industrial sensors is projected to grow from $22.1 billion in 2021 to $34.4 billion by 2026, reflecting an annual growth rate of 9.2%. This increase is driven by the need for advanced data analytics and automation in manufacturing processes.

The advancement of sensor technologies has enabled industries to achieve higher levels of accuracy and reliability. For instance, ultrasonic sensors are widely utilized for non-contact level measurement, providing benefits in terms of safety and maintenance costs. In a recent analysis by ResearchAndMarkets, it was noted that the ultrasonic sensor segment alone is expected to witness substantial growth, attributed to its effectiveness in harsh industrial environments. Additionally, the integration of IoT with sensor technology allows for real-time monitoring and predictive maintenance, reducing downtime and enhancing operational efficiency. The ability to collect and analyze data from top-level sensors not only improves the manufacturing process but also supports sustainability initiatives by minimizing waste and energy consumption.

Level sensors are essential devices used in industrial applications for accurately measuring the level of liquids, solids, and bulk materials. There are several types of level sensors, each designed to function in specific conditions and environments. Among these, capacitive level sensors utilize changes in capacitance caused by the material's presence to provide accurate measurements, making them suitable for detecting levels of non-conductive liquids.

Ultrasonic level sensors, on the other hand, employ sound waves to gauge the distance to the surface of a material, which allows for non-contact measurement in both liquid and solid applications.

Another important category is radar level sensors, which use microwave signals to determine the level of substances. They are particularly effective in challenging conditions, such as high pressure, vacuum, or extreme temperatures, and can measure levels of both liquids and solids with great precision. For applications involving the presence of aggressive chemicals or the need for hygienic standards, guided wave radar sensors provide a robust solution by using a probe immersed in the material to transmit and receive signals. Understanding the different types of level sensors and their functions is critical for optimizing measurement accuracy and ensuring the reliability of industrial processes.

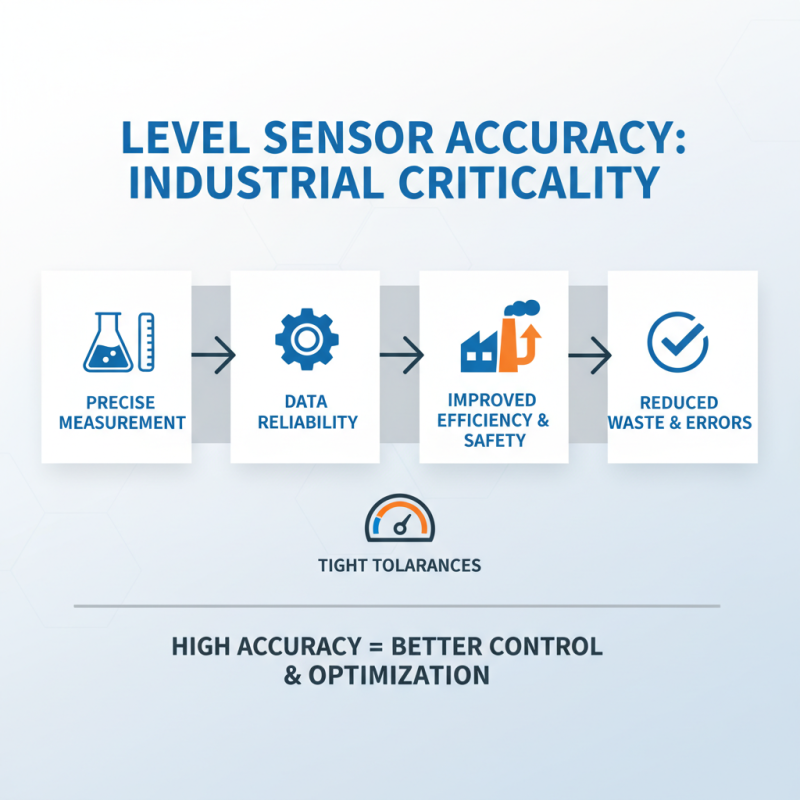

In industrial applications, the selection of level sensors is critical for ensuring precise measurement of various substances. Accuracy stands out as a primary performance metric, as it directly affects the reliability of data used in monitoring and control processes. High accuracy in level sensing allows for improved efficiency, reduced waste, and enhanced safety measures. Industrial settings often require sensors to operate within tight tolerances, making it essential to select devices that minimize measurement errors and provide consistent readings over time.

Range is another crucial performance metric, dictating the capability of level sensors to operate effectively across different applications. Sensors with extended range can adapt to various tank sizes and material types, making them versatile for different industrial environments. This flexibility is important as it allows for the integration of a single sensor type across multiple systems without the need for customization. Additionally, sensitivity is vital for detecting minor changes in level, especially in processes where material volumes can fluctuate dramatically. High sensitivity ensures that even small variations are captured, enabling timely responses to maintain operational efficiency and safety standards.

The integration of level sensors in smart manufacturing and IoT systems represents a significant advancement in the quest for efficiency and precision in industrial applications. Level sensors, which monitor the height of materials in various containers and environments, enable real-time data collection. This information is crucial for maintaining optimal production levels, reducing waste, and ensuring safety in manufacturing processes. By leveraging IoT connectivity, these sensors can communicate with centralized systems, facilitating immediate adjustments based on current conditions and improving overall operational agility.

In a smart manufacturing ecosystem, the synergy between level sensors and IoT devices fosters enhanced decision-making capabilities. The data collected from level sensors contributes to predictive analytics, allowing manufacturers to foresee potential disruptions in the supply chain or shifts in production demand. Furthermore, the integration of these sensors into automated systems supports remote monitoring and control, which is essential for minimizing downtime and maximizing efficiency. As industries continue to embrace digital transformation, the role of level sensors in creating responsive, intelligent manufacturing environments becomes increasingly pivotal.

Accurate level measurement is essential in various industrial applications, leading to substantial efficiency gains across different sectors. In the chemical industry, for instance, studies have shown that utilizing advanced level sensors can reduce product loss due to overflows and underfills. According to a report by the International Society of Automation (ISA), implementing precise measurement technologies can improve operational efficiency by up to 20%, resulting in significant cost savings and increased throughput. These technologies help maintain optimal inventory levels, ensuring that production processes are not interrupted and that safety margins are maintained.

In the food and beverage sector, accurate level sensors enhance quality control and minimize waste. A case study from a leading processing plant highlighted that integrating level measurement solutions reduced ingredient wastage by approximately 15%. With precise monitoring, manufacturers can ensure that their processes adhere to stringent quality standards while optimizing resource usage. The Food Processing Technology journal reported that organizations embracing innovative level measurement strategies saw improvements in both compliance and sustainability, demonstrating how accuracy not only boosts productivity but also contributes to a company’s overall environmental goals. Through these advancements, industries are witnessing transformative benefits that go beyond mere operational metrics.

| Industry | Sensor Type | Efficiency Gain (%) | Measurement Accuracy (%) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Oil & Gas | Ultrasonic Level Sensor | 15 | 98 | 4 |

| Food & Beverage | Radar Level Sensor | 20 | 99 | 6 |

| Water Treatment | Capacitive Level Sensor | 18 | 97 | 5 |

| Chemical | Hydrostatic Level Sensor | 12 | 95 | 7 |

| Pharmaceutical | Laser Level Sensor | 25 | 99.5 | 8 |

As a specialist in environmental and flow sensor technology, ScioSense enables companies to use the planet’s resources more sustainably, helping to create a healthier future for all.