Pressure sensors play a critical role in various industries, from manufacturing to automotive and aerospace. According to a recent market report by MarketsandMarkets, the global pressure sensor market is expected to reach $12.2 billion by 2025, growing at a CAGR of 4.9%. This significant growth highlights the increasing demand for advanced pressure sensing technologies.

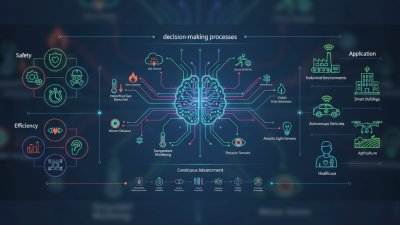

Dr. Jane Miller, a leading expert in sensor technology, emphasizes, “Pressure sensors are essential for enhancing safety and efficiency in industrial applications.” They provide vital information that aids in process control, equipment protection, and overall system performance. With the rise of Internet of Things (IoT) solutions, the integration of pressure sensors into smart devices is also on the rise, pushing innovation forward.

However, not all pressure sensors are created equal. Selecting the right type can be challenging. Different applications require specific features, and understanding these requirements is crucial. Many businesses overlook this, which could lead to inefficiencies. As industries evolve, so does the technology behind pressure sensors, making it essential to stay informed about the top products available. The upcoming list highlights ten noteworthy options worth considering.

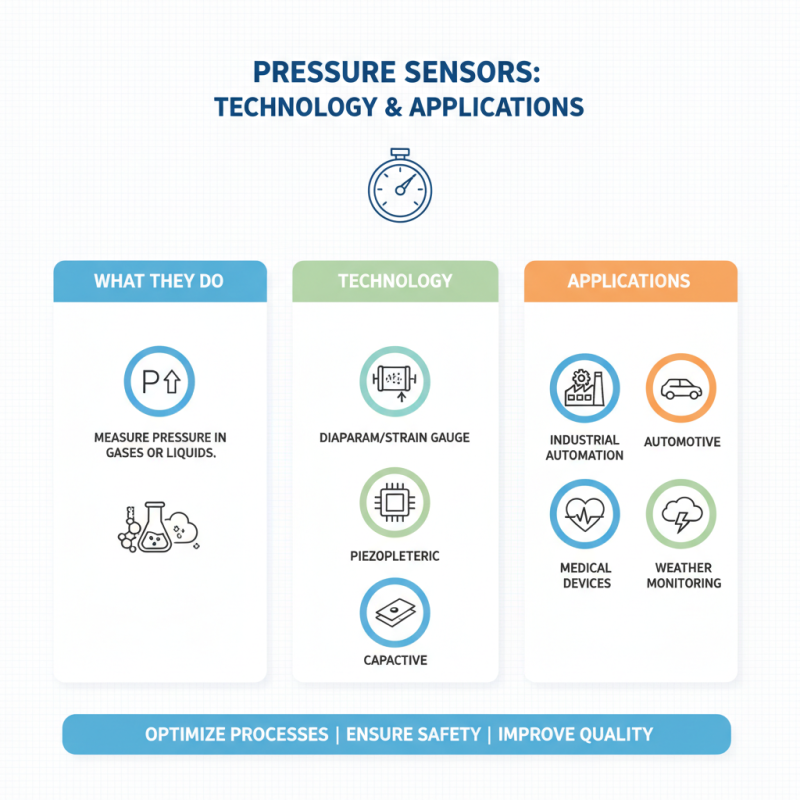

Pressure sensors play a crucial role in various industries. Understanding their technology and applications is essential for optimizing processes. These devices measure pressure in gases or liquids. They help ensure safety, efficiency, and quality in numerous fields.

According to a recent industry report, the global pressure sensor market is expected to reach $8.3 billion by 2026, growing at a CAGR of 6.2%. This growth is driven by advancements in sensor technology, including MEMS and piezoresistive sensors. Many industries, including automotive, aerospace, and healthcare, rely on accurate pressure readings for critical operations. In automotive applications, for example, sensors enhance engine performance and fuel efficiency.

Despite their benefits, some challenges remain. The calibration process can be complex and time-consuming. Inaccurate readings can lead to costly errors. A recent survey indicated that approximately 30% of users experience calibration issues. Continued innovation and better training could improve accuracy. Addressing these challenges is vital for the ongoing development of pressure sensor technology.

When evaluating pressure sensors, reliability and accuracy are paramount. A good sensor should have a low hysteresis, which refers to the difference in readings during increasing and decreasing pressure. This inconsistency can lead to serious errors in critical applications. Materials used in construction also play a key role. They must withstand harsh environments without degrading. Many sensors fail due to insufficient material choices.

Another important parameter is temperature compensation. Pressure sensors that do not account for temperature fluctuations may deliver inaccurate results. This is especially crucial in industries where temperature varies significantly. Calibration is another factor, but often overlooked. Regular calibration ensures that sensors maintain their accuracy over time. Some users neglect this step, which can lead to unnoticed drift.

Consider the response time of a pressure sensor. Slow response times can affect process control and lead to unsafe conditions. Additionally, the power supply should be stable. An unreliable power source can introduce errors in readings. While many focus only on the final output, the entire system's health is vital. This reflection can help improve overall efficiency and safety in measurements.

| Sensor Type | Pressure Range | Accuracy | Output Signal | Operating Temperature |

|---|---|---|---|---|

| Piezoelectric | -1 to 1000 Bar | ±0.5% | Voltage Output | -40 to 125 °C |

| Strain Gauge | 0 to 300 Bar | ±0.1% | Current Output | -20 to 85 °C |

| Capacitive | 0 to 10 Bar | ±0.2% | Voltage Output | -20 to 70 °C |

| Optical | 0 to 500 Bar | ±0.5% | Digital Output | -30 to 120 °C |

| Silicon Piezo-resistive | 0 to 100 Bar | ±0.25% | Analog Output | -40 to 85 °C |

| Bourdon Tube | 0 to 50 Bar | ±1% | Analog Signal | -20 to 60 °C |

| Membrane | 0 to 20 Bar | ±0.4% | Current Output | -10 to 85 °C |

| Digital Pressure Sensors | 0 to 1000 Bar | ±0.1% | Digital Output (I2C, SPI) | -40 to 85 °C |

| Hydraulic | 0 to 400 Bar | ±0.5% | Analog Output | -20 to 80 °C |

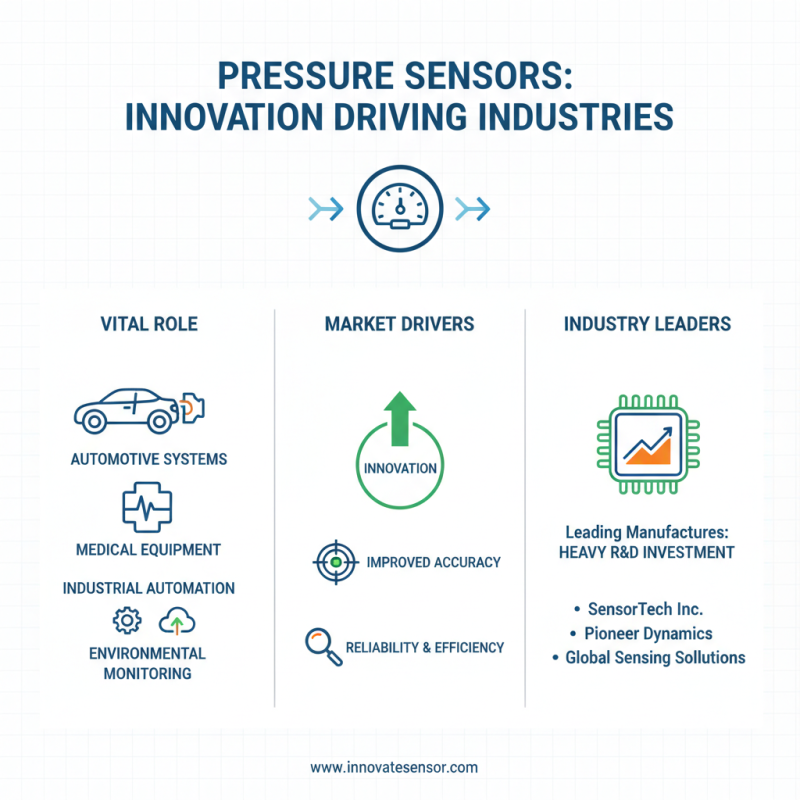

Pressure sensors play a vital role in various industries. Their applications range from automotive systems to medical equipment. The market is driven by innovations and the need for better accuracy. Many companies are leading the way in sensor manufacturing. These players invest heavily in research and development. They focus on creating more reliable and efficient devices.

Not every product meets high standards. Quality control can be inconsistent. Some sensors may not perform well under extreme conditions. This leads to potential failures in critical systems. Customers often face challenges in finding the right solutions. The landscape can be overwhelming, with so many options available. Industry players are addressing these issues by enhancing their offerings, but challenges remain.

Collaboration among manufacturers, researchers, and suppliers is crucial. This could lead to improved designs and better performance. The ongoing pursuit of excellence in pressure sensor technology never truly ends. Adapting to new market demands is essential for long-term success in the industry. Companies must evolve constantly to keep up with advancements and consumer needs.

In 2023, pressure sensor technology is evolving rapidly. Significant trends shape the market. Miniaturization is key. Smaller sensors offer more versatility. This trend allows integration into compact devices. Manufacturers are focusing on creating lightweight sensors without sacrificing performance.

Wireless technology is also on the rise. A growing number of sensors feature wireless connectivity. This development enables remote monitoring and data collection. Users benefit from real-time insights without being tethered to devices. However, reliance on batteries raises concerns. Wireless sensors must balance reliability with energy efficiency.

Another trend involves enhanced materials. Advanced materials improve durability and accuracy. New coatings protect sensors from harsh environments. Yet, some materials may not be suitable for all applications. Users should consider environmental compatibility before selection.

Tips: Always evaluate the environment where the sensor will be used. Understand the specific requirements of your application. Research the latest materials and technologies for optimal performance.

Pressure sensors are vital in many industries. They measure the force exerted by gases or liquids. These sensors enhance efficiency, safety, and performance across various applications. In manufacturing, they monitor equipment to prevent malfunctions. A small leak can lead to costly downtime. Pressure sensors help detect these issues early.

In the automotive sector, pressure sensors are crucial. They ensure optimal engine performance. For example, they monitor tire pressure to avoid accidents. Proper tire pressure improves fuel efficiency. In healthcare, these sensors play a key role in patient monitoring. They track blood pressure, providing real-time data to doctors. Accurate readings can save lives.

Despite their benefits, challenges exist. Some sensors may fail under extreme conditions. Environmental factors can affect their accuracy. Regular maintenance is necessary to ensure reliability. Additionally, sensor costs can be a barrier for smaller businesses. Investing wisely in technology is essential. Balancing cost with quality is a difficult task.

As a specialist in environmental and flow sensor technology, ScioSense enables companies to use the planet’s resources more sustainably, helping to create a healthier future for all.