Choosing the right high temperature pressure sensors for specific applications can be daunting. Experts in the field highlight various factors to consider. Dr. Emily Carter, a renowned engineer, once stated, “Selecting the appropriate sensor can significantly impact performance and safety.” This emphasizes the importance of thoughtful selection.

High temperature pressure sensors are essential in industries like aerospace and manufacturing. They withstand extreme conditions. However, not all sensors are created equal. Understanding your application’s needs is critical. Factors like pressure range, temperature limits, and material compatibility must be evaluated.

Many users overlook these aspects, leading to costly errors. Sensor failures can result in operational downtimes. It’s vital to reflect on these choices. Mistakes in selection can compromise safety and efficiency. Therefore, careful research is needed to ensure optimal outcomes.

High temperature pressure sensors are essential in many industries, such as aerospace and manufacturing. They must withstand extreme environments while providing accurate readings. Understanding the specifications of these sensors is crucial for selecting the right one for your application.

When looking at high temperature pressure sensors, consider the operating range. Many sensors can perform effectively at temperatures exceeding 200°C. Some specialized sensors can handle temperatures up to 800°C. You should also review their pressure ranges. A study shows that pressure sensors typically operate between 0 to 5000 psi, depending on the design. Power consumption is another vital factor, especially in remote locations.

Tip: Always evaluate your specific application needs before purchasing. Review calibration requirements and connection types. Not all sensors are compatible with every system.

Accuracy is paramount. Look for sensors with a low percentage of linearity error. While technologies like piezoelectric sensors offer high precision, they may not suit all applications. Assessing the trade-offs between accuracy and durability is crucial.

Tip: Check if the sensor can operate under the electromagnetic interference common in many industrial settings. This consideration often gets overlooked but can significantly impact sensor performance.

When selecting high temperature pressure sensors, key properties play a crucial role.

Temperature ranges are essential. Many applications require sensors capable of enduring extreme heat.

For example, sensors designed for environments exceeding 300°C often utilize advanced materials. These materials resist thermal degradation.

Understanding these limits ensures reliability.

Accuracy and sensitivity are critical characteristics. Pressure sensors should provide precise readings,

especially in high-temperature conditions. Reports indicate that a 0.1% accuracy rating is standard for many applications.

In industries like petrochemical, slight deviations can lead to significant risks. It's vital to understand the specifications before making a choice.

Additionally, the construction of the sensor impacts durability and performance. Stainless steel casings are common.

Yet, they may not be enough for every application. Some environments require specialized coatings to withstand corrosive elements.

This fine-tuning can determine sensor longevity. Failure to consider these aspects can lead to operational challenges.

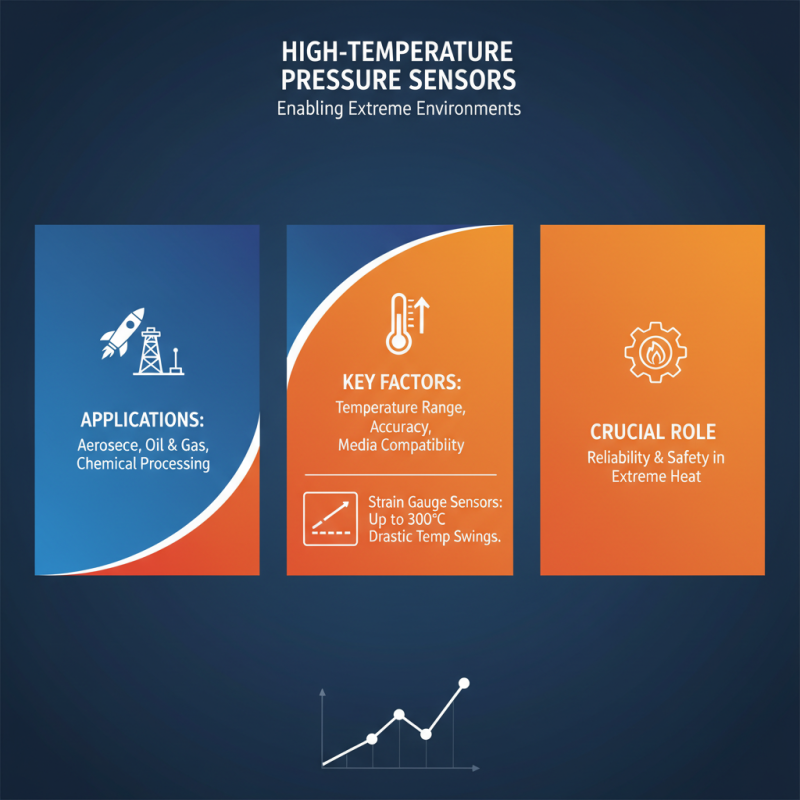

High temperature pressure sensors play a crucial role in industries such as aerospace, oil and gas, and chemical processing. Different types of sensors are suitable for specific applications, depending on factors like temperature range, accuracy, and media compatibility. For example, strain gauge sensors are capable of withstanding temperatures up to 300°C. They are often used in environments with drastic temperature fluctuations.

Another type is capacitive pressure sensors, which can operate at temperatures as high as 500°C. These sensors offer high sensitivity and are ideal for applications involving aggressive media, like corrosive chemicals. According to a report by IMARC Group, the global pressure sensor market is expected to reach $5.2 billion by 2027, indicating a growing demand for these high-temperature solutions.

Thermocouple-based sensors also deserve attention. They provide not only pressure measurements but also temperature readings. However, their installation can be tricky, requiring careful calibration. Reports suggest that improper installation could lead to a drift in measurements. With the right selection criteria, industries can avoid some common pitfalls. Balancing cost with necessary accuracy often leads to critical decisions that require reflection on long-term operational needs.

When installing high-temperature pressure sensors, the environment plays a critical role. The choice of mounting location can impact the sensor's performance. Ensure the sensor is placed away from heat sources and vibration. This can significantly enhance its accuracy.

Consider the material compatibility too. Many sensors may corrode or malfunction in harsh conditions. A sensor exposed to chemicals might degrade faster. Pay attention to sealing methods. Gaskets and O-rings help protect sensors from contaminants. Their choice should match the environment as closely as possible.

Testing is vital during installation. A sensor may look robust but still be unreliable. Monitor its performance in real conditions. Make adjustments based on any discrepancies observed. Regular checks can help maintain accuracy over time. Proper installation often requires multiple attempts. Don't hesitate to rethink your approach if issues arise.

| Parameter | Application Environment | Operating Temperature (°C) | Pressure Range (Bar) | Output Type |

|---|---|---|---|---|

| Material Compatibility | Chemical Processing | -40 to 150 | 0-250 | 4-20 mA |

| Sensor Type | Manufacturing | -20 to 200 | 0-500 | Voltage Output |

| Sealing Type | Oil & Gas | -50 to 300 | 0-1000 | Digital |

| Calibration | Aerospace | -40 to 400 | 0-2000 | RS485 |

Maintaining high temperature pressure sensors is crucial for their optimal performance. Regular checks ensure sensors operate accurately. Over time, sensors can drift. This drift impacts the readings and can lead to significant errors. Calibration should be performed at set intervals. Keeping a calibration log helps track these activities.

Environmental factors can affect sensor performance. For instance, extreme temperatures may cause wear. Dust and moisture can interfere with functionality. Regular cleaning is essential to extend sensor life. Use appropriate cleaning agents to avoid damage.

Improper installation can also hinder performance. Ensure the sensor is correctly mounted and aligned. A small error during installation can lead to faulty readings. It’s vital to periodically review installation procedures. This helps identify potential areas for improvement. Consistent maintenance practices can boost sensor reliability.

As a specialist in environmental and flow sensor technology, ScioSense enables companies to use the planet’s resources more sustainably, helping to create a healthier future for all.