In the rapidly evolving landscape of technology, the significance of barometer sensors cannot be overstated. As industries increasingly rely on accurate atmospheric pressure readings for applications ranging from weather forecasting to altitude measurement in drones, the demand for high-quality barometer sensors is surging. According to a recent market research report by Technavio, the global barometer sensor market is projected to reach $2.3 billion by 2025, highlighting the pivotal role these sensors play across various sectors.

Dr. Sarah Lin, an esteemed expert in sensor technologies, remarked, "The advancement of barometer sensors is crucial for enhancing environmental monitoring and improving the efficiency of navigation systems." Her insights emphasize the importance of selecting the right sensor for your specific project needs. This guide aims to illuminate the criteria and features to consider when choosing the best barometer sensors available in the market, ensuring that engineers and developers can make informed decisions to optimize their projects.

As we delve into the "Top 5" considerations for selecting barometer sensors, understanding their functionalities, accuracy, and integration capabilities will be paramount for success in any application.

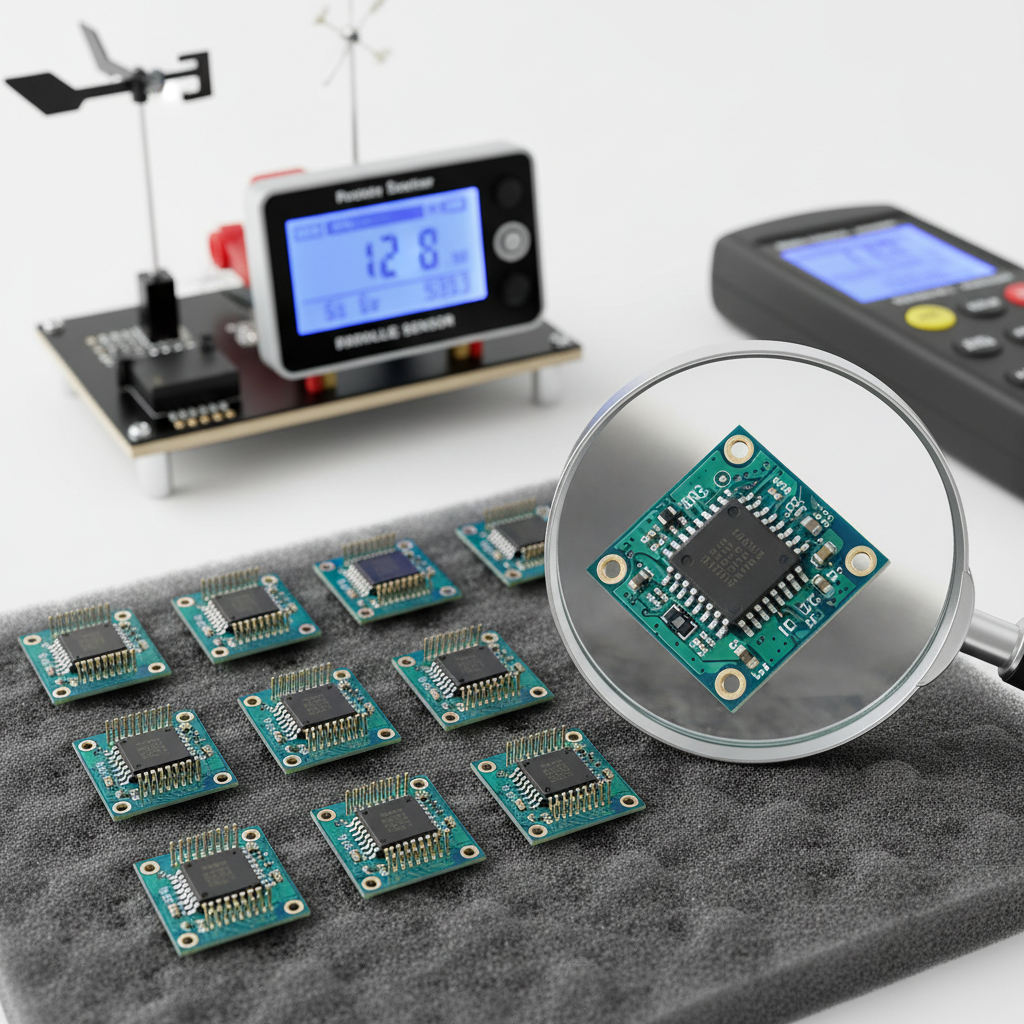

When selecting barometer sensors for your projects, understanding key specifications is essential. First and foremost, consider the sensor's pressure range and accuracy. The pressure range will determine its applicability for various environments, while accuracy is crucial for precise measurements in applications such as weather forecasting or altitude tracking.

Another important specification is the sensor's resolution and response time. High resolution will ensure that even small changes in atmospheric pressure are detected, which is particularly important in applications that require real-time data. Additionally, a fast response time allows the sensor to adapt quickly to environmental changes, making it suitable for dynamic conditions.

Tips: When evaluating potential sensors, it's beneficial to look for additional features such as temperature compensation and calibration options. Temperature changes can affect pressure readings, so sensors with built-in compensation can provide more reliable data. Also, check if the manufacturer provides easy calibration resources, which can significantly enhance the adaptability of the sensor in different projects.

When it comes to choosing the best barometer sensors for your projects, understanding measurement accuracy is vital. Accuracy in measurement can significantly impact the quality of building information models (BIM) and other projects requiring precise data. For example, the AEC industry increasingly relies on advanced technology like scan to BIM, which demands high accuracy to ensure reliable outputs. According to industry reports, measurement errors can lead to costly reworks—emphasizing the importance of devices that conform to recognized industry standards.

**Tips:** Always check the specifications of barometer sensors against recognized accuracy standards relevant to your industry. Look for sensors that provide a detailed error margin and can operate effectively under varying environmental conditions. This ensures that your measurements will be reliable and accurate throughout your project lifecycle.

Moreover, it's essential to understand the calibration and maintenance requirements of these sensors. Regular calibration to industry standards can help maintain high accuracy levels. With emerging technologies enhancing sensor reliability, it is now more feasible to achieve levels that meet or exceed industry norms, such as those referenced in specific measurement certifications. By choosing the right sensor, you are not only ensuring precise measurements but also enhancing overall project success.

Choosing the right barometer sensors for your projects requires a deep understanding of environmental conditions, particularly temperature and humidity. These factors can significantly influence sensor performance and accuracy. As the global market for battery-free sensors is projected to reach $5.57 billion by 2025, with an anticipated growth rate of 6.6% leading to a value of $9.5 billion by 2033, it is clear that the demand for innovative sensor technologies is on the rise. This growth underscores the importance of selecting sensors that can withstand various environmental conditions without compromising their functionality.

Barometer sensors, which are instrumental in detecting changes in atmospheric pressure, are susceptible to the temperature and humidity levels of their surroundings. High humidity can cause condensation within sensor enclosures, while temperature fluctuations can affect the physical properties of the materials used in sensors. Accordingly, understanding these environmental impacts is vital for ensuring the longevity and reliability of barometric readings. A thorough assessment of these conditions will not only enhance sensor selection but will also provide valuable insights for optimizing IoT applications, such as automated irrigation systems and environmental monitoring setups.

When selecting barometer sensors for your projects, evaluating sensor sensitivity is critical to ensuring accurate and reliable measurements. Sensitivity refers to the smallest change in pressure that the sensor can detect and quantify. According to a report from the International Society for Automation, high-performance barometric sensors can achieve sensitivity levels below 0.01 hPa, allowing for precise monitoring of atmospheric changes. This level of sensitivity is particularly essential in applications requiring real-time data, such as weather forecasting and environmental monitoring.

Additionally, a study conducted by Research and Markets indicates that the demand for highly sensitive barometer sensors is projected to increase by 15% annually through 2025. This trend is driven by advancements in technology, including digital signal processing and miniaturization, which enhance the performance of these sensors. Therefore, when choosing a barometer sensor, consider not only the specifications provided by manufacturers but also how well they align with the specific sensitivity requirements of your project. Meeting project demands with precision hinges on selecting the right sensor capable of providing accurate pressure readings, ultimately influencing the reliability of your project's outcomes.

When selecting barometer sensors for your projects, understanding the differences between digital and analog types is crucial. Digital barometer sensors offer high precision and can provide direct readings of atmospheric pressure through digital communication interfaces like I2C or SPI. This accuracy makes them ideal for applications where precise environmental data is essential, such as in weather stations or altimeters. Moreover, digital sensors typically feature built-in calibration, reducing the need for manual adjustments and enhancing reliability in long-term monitoring scenarios.

On the other hand, analog barometer sensors may present a simpler circuit implementation and are often more cost-effective. These sensors output a continuous voltage signal corresponding to the pressure level, making them suitable for applications where rapid response times and real-time monitoring are required. However, they can require additional components for signal conditioning and may not achieve the same level of precision as their digital counterparts. Ultimately, the choice between digital and analog barometer sensors depends on the specific requirements of your project, including budget constraints, required accuracy, and the complexity of the intended application.

As a specialist in environmental and flow sensor technology, ScioSense enables companies to use the planet’s resources more sustainably, helping to create a healthier future for all.