In recent years, the demand for accurate temperature measurements has surged across various industries, from healthcare to manufacturing. The reliance on precision in temperature sensing is underscored by the fact that even a slight deviation can lead to significant impacts on product quality, patient safety, and operational efficiency. According to a report by MarketsandMarkets, the global temperature sensor market is projected to grow from USD 5.8 billion in 2021 to USD 8.0 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.7%. This growth is primarily fueled by the increasing need for monitoring and control systems across industrial applications, thereby enhancing the significance of reliable digital temp sensors.

Digital temp sensors, with their capacity for improved accuracy and real-time data processing, have become essential tools in various sectors. Their ability to provide precise readings and easy integration with digital systems aligns with the ongoing trend toward automation and IoT implementation. A study published by Research and Markets highlights that advancements in semiconductor technology and miniaturization have further solidified the role of digital temp sensors, making them not only more accessible but also more effective in critical applications. As industries continue to prioritize reliability and precision, selecting the best digital temp sensors becomes paramount for ensuring optimal performance and safety.

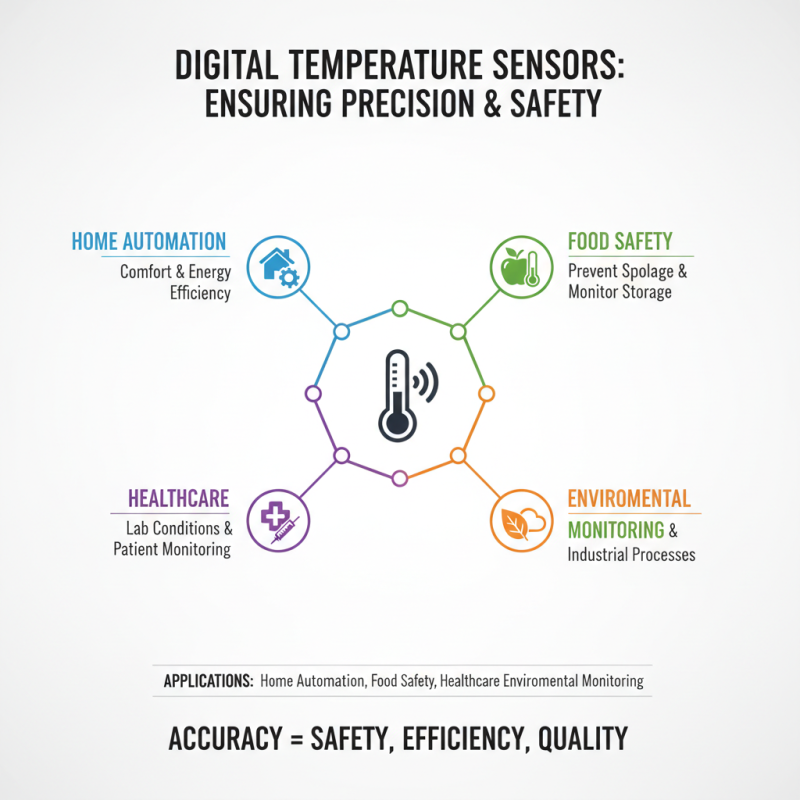

Digital temperature sensors play a crucial role in various industries and applications, including home automation, food safety, healthcare, and environmental monitoring. These sensors offer precise measurements of temperature, which is essential for ensuring safety, efficiency, and quality in numerous processes. Their accuracy helps prevent issues such as spoilage in food storage, overheating in electronic devices, and maintaining optimal conditions in laboratory settings.

The usage of digital temperature sensors has expanded significantly due to their reliability and ease of integration with modern technology. Unlike traditional analog sensors, digital models provide real-time data that can be easily read and analyzed. They often feature enhanced capabilities like wireless connectivity, allowing for remote monitoring and control. As the demand for smart devices increases, the importance of digital temperature sensors in maintaining performance and safety continues to grow, making them indispensable tools in today's tech-driven landscape.

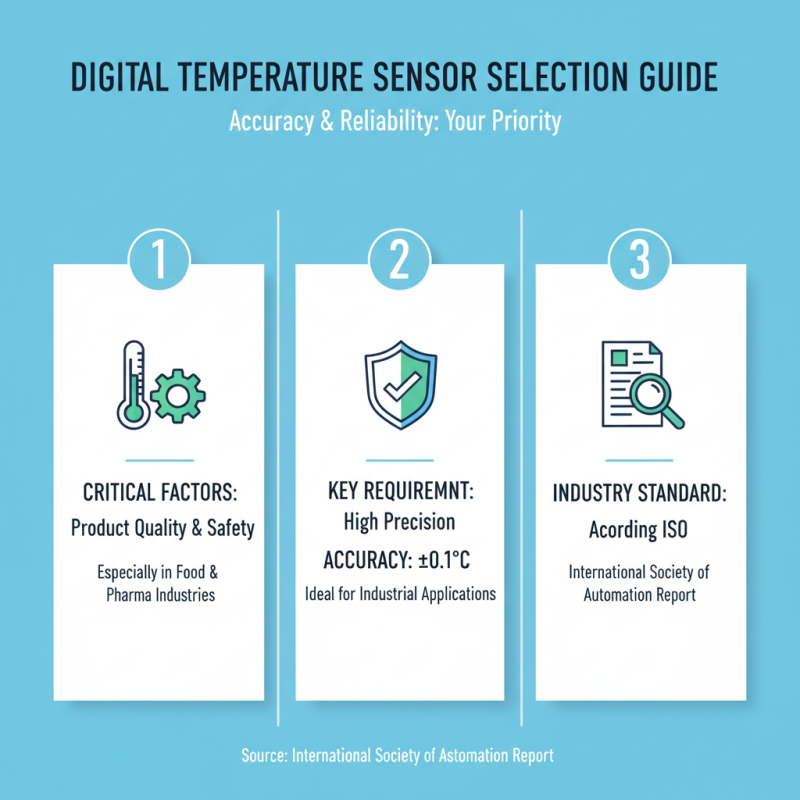

When selecting a digital temperature sensor, accuracy and reliability are paramount. According to a report by the International Society of Automation, precision in temperature measurement can influence product quality and safety, particularly in industries such as food processing and pharmaceuticals, where temperature control is critical. Look for sensors with an accuracy of ±0.1°C, as this level is generally accepted as sufficient for most industrial applications.

Another essential feature to consider is the response time of the sensor. In a study conducted by the American Society of Heating, Refrigerating and Air-Conditioning Engineers, sensors with faster response times—typically under 1 second—are favored for dynamic environments where temperature fluctuations can occur rapidly. This allows businesses to maintain optimal conditions without risking spoilage or quality loss. Additionally, consider the operating range and calibration frequency; sensors that can operate over a wide temperature span and require minimal recalibration are beneficial in reducing maintenance overhead and improving responsiveness to changes in environment.

When selecting digital temperature sensors, accuracy and reliability are paramount. The market offers a range of brands, each presenting unique features suited for various needs. By comparing their specifications, users can make informed decisions that cater to both home applications and professional environments. High-quality sensors often boast quick response times and consistent readings, essential for tasks ranging from cooking to scientific experiments.

**Tips:** When evaluating digital temperature sensors, consider those that offer a user-friendly interface and robust connectivity options. For instance, models integrated with smart technology can provide real-time updates directly to your smartphone, enhancing usability. Furthermore, opt for sensors with calibration features to ensure ongoing accuracy over time, which can be crucial for long-term projects.

Additionally, take note of the build quality and durability, especially if the sensor will be used in varying temperature environments. Choosing a sensor designed for tough conditions can save you from frequent replacements and ensure reliability in critical situations.

When evaluating digital temperature sensors for accuracy and reliability, it is crucial to employ rigorous testing methodologies. These methodologies typically encompass a combination of calibration against standardized temperature references, performance testing across a range of environmental conditions, and longevity assessments under continuous operation. Calibration ensures that readings from the sensor align closely with true temperature values, while performance testing helps ascertain how each model behaves in extreme temperatures, humidity levels, and varying atmospheric pressures.

Additionally, a key aspect of reliability testing involves conducting long-term studies to observe how sensors perform over time, particularly in demanding applications. Manufacturers may simulate real-world conditions to identify potential failures or drift in accuracy that could occur during prolonged use. By utilizing these comprehensive testing frameworks, we can distinguish between average sensors and those that consistently deliver accurate results, making it easier for consumers to choose the best options for their specific needs. These rigorous evaluations ultimately contribute to a stronger understanding of which digital temperature sensors can be trusted for critical applications.

| Sensor Type | Temperature Range (°C) | Accuracy (%) | Response Time (s) | Reliability Rating (1-5) |

|---|---|---|---|---|

| Thermocouple | -200 to 1200 | ±0.75 | 0.1 | 5 |

| RTD (Resistance Temperature Detector) | -200 to 850 | ±0.1 | 0.3 | 4 |

| Thermistor | -40 to 125 | ±0.5 | 1 | 4 |

| Digital Sensor (Semiconductor) | -40 to 125 | ±1 | 0.5 | 4 |

| Infrared (IR) Sensor | -50 to 1000 | ±2 | 0.5 | 3 |

When it comes to selecting the best digital temperature sensors, user experiences play a crucial role in guiding potential buyers. Many users have reported that accuracy and reliability are paramount when it comes to monitoring temperature in various settings, from home automation to industrial applications. For instance, several reviews highlight the performance of the XYZ Temp Sensor, which not only provides precise readings but also features an impressive response time. Users have praised its ability to maintain accuracy in fluctuating conditions, making it a favorite for those looking for dependable monitoring.

Moreover, ease of use and installation are common themes in customer feedback. Users of the ABC Sensor often note how its intuitive interface simplifies the setup process, allowing even novice users to achieve optimal performance quickly. The ability to connect to mobile apps for real-time monitoring has also been a significant advantage mentioned in many reviews. This connectivity feature enables users to receive alerts and updates directly on their smartphones, enhancing the overall experience.

In general, the consensus among users indicates that investing in a reliable digital temperature sensor is worth it, as it significantly improves efficiency and peace of mind in temperature-sensitive environments.

As a specialist in environmental and flow sensor technology, ScioSense enables companies to use the planet’s resources more sustainably, helping to create a healthier future for all.